Kiwiastur offers the consumer a Kiwifruit as if it had just been picked from the tree. To achieve this, after a careful manual harvesting on our farms, it undergoes a delicate and exhaustive process of reception, cleaning, conservation, calibration, packaging and labelling using specific machinery, but always under human supervision.

Facilities

Reception and storage

When it arrives at our facilities, each batch is identified and controlled by farmer, Brix grade, dry matter, plantation, harvest date, lot, etc.

Once received, the fruits spend a minimum of 24 hours in the drying area so that the wounds caused on the peduncle during harvesting heal naturally.

From there they are transferred to cold storage and controlled atmosphere chambers to achieve optimum conservation, slowing down ripening and avoiding losses due to rotting.

The cold rooms cool the fruit graduallyreaching the storage temperature 10 or 15 days after reception, depending on the inlet temperature.

They also have ethylene and disease control equipment that sterilizes the air in the chambers themselves using electric currents, and humidifiers that help to maintain the smoothness and integrity of the fruits.

When they come out of the chambers, the kiwis follow their natural process.

Calibrating and packaging

To guarantee uniformity in the classification of the fruit, its presentation for distributors and the conditions in which it reaches the final consumer, we work"just in time"preparing and packing the Kiwifruit after receiving the client's order.

In the sorting machine, unsuitable kiwis are removed manually in a first filter. Then they pass through a detector camera where those that present deformities are eliminated. At this point they are also brushed to remove the possible remains of soil and the typical hair of this fruit.

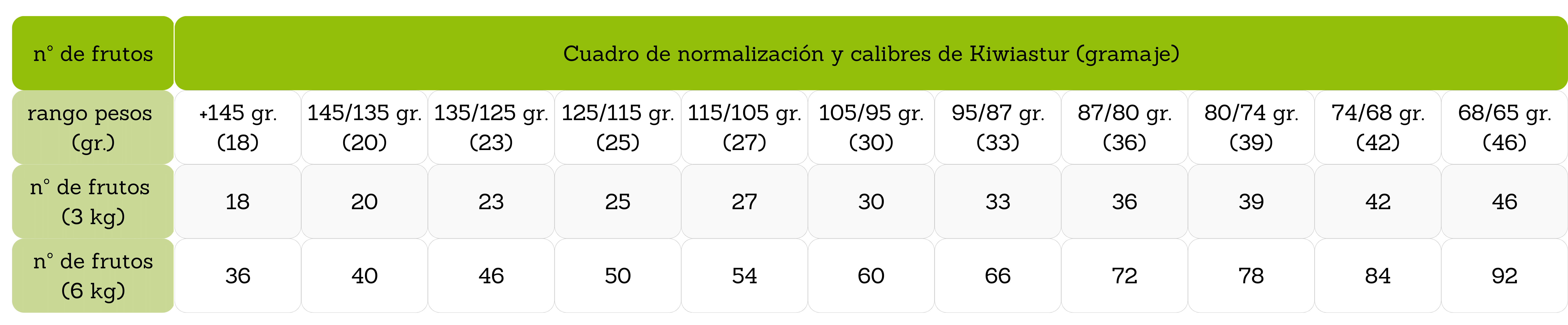

Calibration complies with regulation (EC) No 1673/2004 of 24 September 2004,which establishes the marketing standard applicable to kiwis in the EU..

The Kiwifruit is packaged in a standardised form, although customisation can be considered on a case-by-case basis.

Expedition

The packaged kiwis , pallets of different sizes are prepared, depending on the customer to whom they are addressed.

Each box is identifies with its lot and traceability, and pass to the dispatch chambers, where they are cold until the refrigerated trucks pick them up to their destination.

In this handling phase, temperature, relative humidity and ethylene levels are also controlled to keep the fruit in optimal conditions.

To distribute Kiwiastur in your establishment, contact us: